Drawings must be 1:1 scale and in mm (millimetres). Please show a scale bar.

File types for 2D projects DWG, DXF or Ai files.

For 3D projects IGES or STEP

If you have material to cut but don't have the machines, or simply the time, we'll cut it for you. Please fill in your details and upload your files below, or by e-mail to info@buildingbloqs.com. We will estimate the most efficient way to cut it and get back to you.

Please fill in your details and give us as much information about your project and upload any relevant files. We can come back to you as soon as possible.

Drawings must be 1:1 scale and in mm (millimetres). Please show a scale bar.

File types for 2D projects DWG, DXF or Ai files.

For 3D projects IGES or STEP

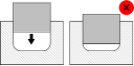

What do we mean by offset for CNC routing? The CNC router will interpret and cut a line in 3 ways.

You must state in your drawing if the cut is to be on, inside or outside of the line.

Include as much detail in your drawing as possible. Include notes and label the layers to show the characteristic of that layer for instance the cut depth, shape and size of profiles. It is helpful to assign colours to the different layers. For example:

Layer 1: Cut through, offset outside line.

Layer 2: Engrave 2mm, offset inside line.

Layer 3: Pocket to 9mm

Our CNC machine bed will hold material up to 3100mm x 1600mm.

Please illustrate your sheet size with dimensions on your CAD file.

The maximum thickness we can cut is 90mm

Spacing Components - 'Nesting'

It’s important to get as much from your materials as possible. The way your parts are laid out (nested) on a sheet will affect material efficiency and cutting time. Please follow the guides below for guidance on nesting components on your sheet.

-5mm distance between parts and edge of sheet.

-15mm distance between parts on a sheet.

-30mm distance between smaller parts – (see ‘small parts’)

Small parts are anything smaller than 300mm x 300mm or thinner than 100mm.

Small parts tend to want to move during cutting. The CNC machine has a vacuum that sucks the material to the cutting bed. With a smaller surface area the vacuum is less effective. To get around this we may add holding tabs to keep the small parts in place, like a model aircraft kit. You must therefore allow 30mm spacing around small components to allow for the holding tabs.

The holding tabs are also called Onion skins.

Tabs and Onion skins defined:

Onion skin: leaves a paper-thin bit of material at the bottom of a profile cut.

Tabs: generally larger and thicker, which because of their size, don’t always work well for small parts.

Both can be hand cut or sanded off, or removed by CNC as an extra pass, but would incur additional cost/time.

|

|

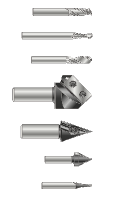

As a general rule the thicker your material, the more passes are needed to cut through it. By increasing the size of the cutter, the deeper we can cut in one pass. So, using a wider diameter cutter is more efficient as more material is removed faster. Also, the machines can cut to any depth, not just all the way through. |

The CNC machine can cut an internal area of any shape to any specified depth. This is called a ‘pocketing’ operation. It is worth factoring in that ‘Pocketing’ can take a lot of time if the area is large, and internal corners of pocketing operations will have a radius equal to the cutter.

|

Standard cutter sizes are 6mm, 8mm, 12mm diameter and so on. Different cutters are available, if you need a specific cutter or advice please contact us. |

|

|

All cutters are circular. The radius left on any internal corner will be equal to the radius of your chosen cutter. For example an 8mm diameter cutter will leave a 4mm radius on any internal corner. Round cutters leave small radiuses on internal corners, these can get in the way if a square part is to be inserted. Dog bone or T-bone fillets can be used which over-cut corners and allow square parts to mate. |

|

|

|

|

Radius corners will be cut as standard, please specify if you would like dog bone or t-bone fillets cut. We can add these to your drawings for you.

|

It is important to illustrate holes on your drawing by both the hole diameter (circle) and the centre point. Holes must be 1:1 scale. |

Cookie Policy

This website uses a number of essential cookies to operate. Please read our privacy policy for more information